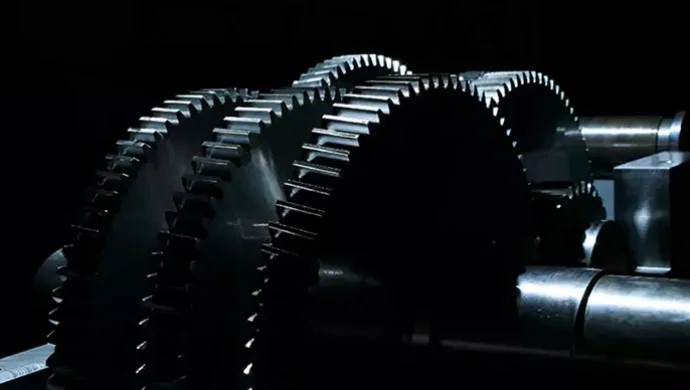

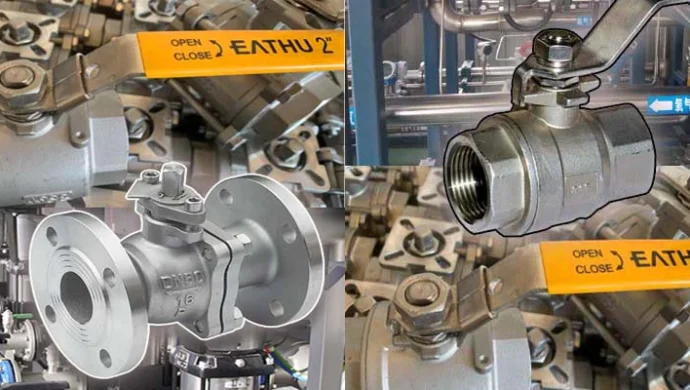

This paper provides an in-depth analysis of the machine tool casting casting process, covering the multi-step process from metal melting, casting, cooling and solidification to finishing, and elaborates on the key points of each process, including the key role of process parameters, the importance of the quality of the casting mold and liquid metal, and analyzes the advantages of machine tool castings such as good vibration damping, high-temperature resistance, and good process performance, etc. At the same time, it also introduces the excellent contributions of EATHU in the application of environmental protection technology, optimization of process parameters, material research and development, supply and quality assurance system. At the same time, it introduces EATHU's excellent contribution in the application of environmental protection technology, optimization of process parameters, material research and development, and quality assurance system, which provides a comprehensive technical reference and industry development example for machine tool castings manufacturing.