With more than 3,000 customers worldwide, Eathu has always gained the trust and recognition of its customers by providing high quality products and services.

Eathu has a strict quality management system, we have professional quality inspectors to check and monitor the raw materials, production process and finished products to ensure that each sand casting part meets the requirements and standards of customers.

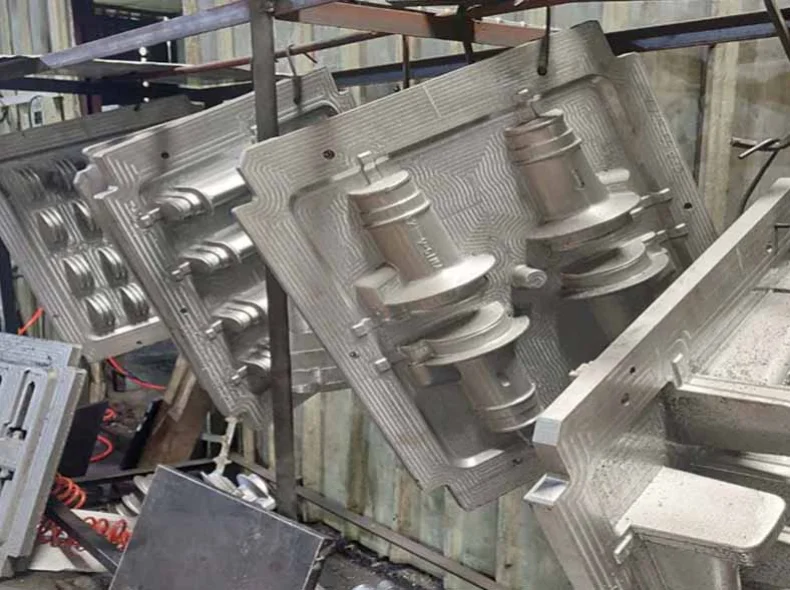

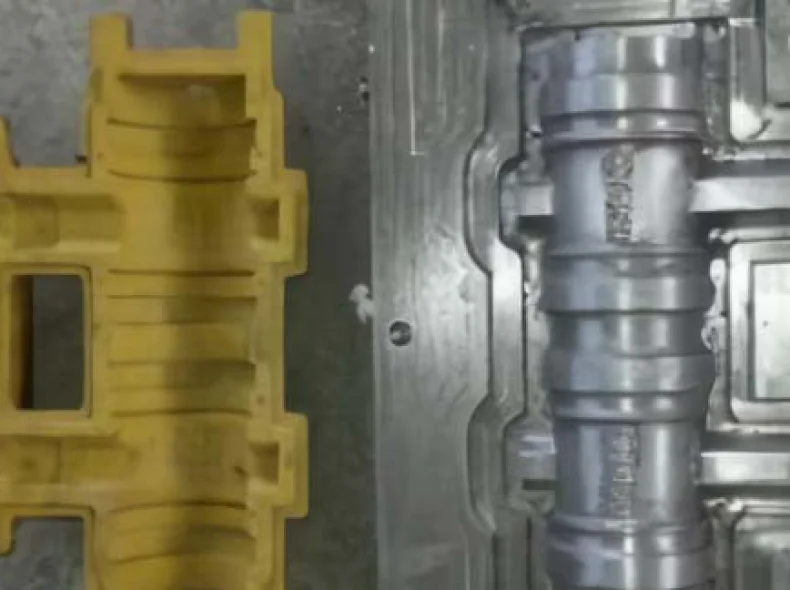

With advanced casting equipments and processes, Eathu adopts precise mould design and casting process to ensure the accuracy and consistency of castings. Combined with CAD/CAM technology, the shape and size of the castings are precisely controlled to avoid defects and deformation caused by the casting process to the maximum extent.

During the sand casting process at Eathu, the quality of the castings is verified through a number of procedures.

1. Check that the surface of the sand mould is flat and free from cracks and deformations

2. Checking that the dimensions, wall thicknesses, angles, etc. of the cast rows are in accordance with the design requirements.

3. Analyse the chemical composition of the melt and check the metallographic structure.

4. Observe the filling condition of melt during pouring process, whether there are defects such as slag folder or air hole.

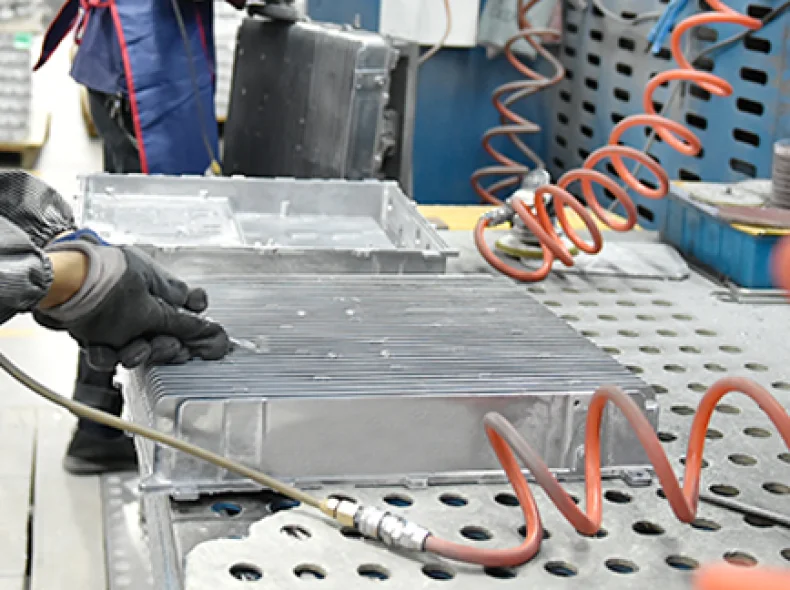

5. After the casting is completed, take samples of the products for inspection, check the product size, surface quality, etc.

6. Use instruments to check the internal defects of castings, grain boundaries, test the strength and hardness of castings, etc.

Through these inspections, we can find and solve the quality problems in time, and the problem pieces will not leave the factory.

We specialise in producing high quality sand castings.

Moreover, Eathu focuses on communication with customers, and improves and optimises the sand casting service according to customers' continuous feedback.

Because of Eathu's emphasis on quality, we have been awarded the ISO9001 certificate, which is Eathu's affirmation and guarantee to our customers.