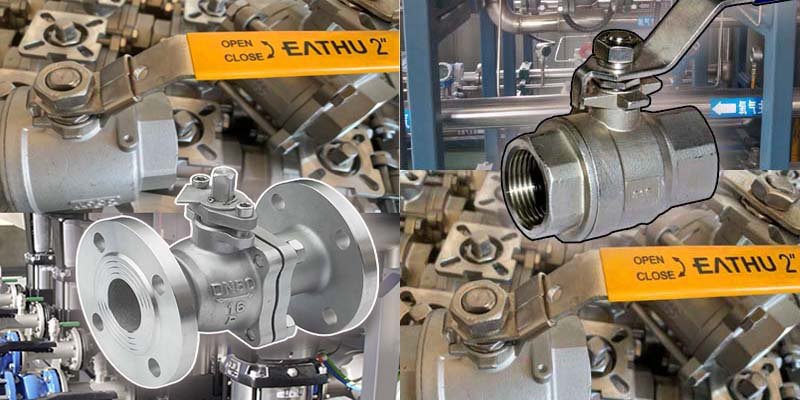

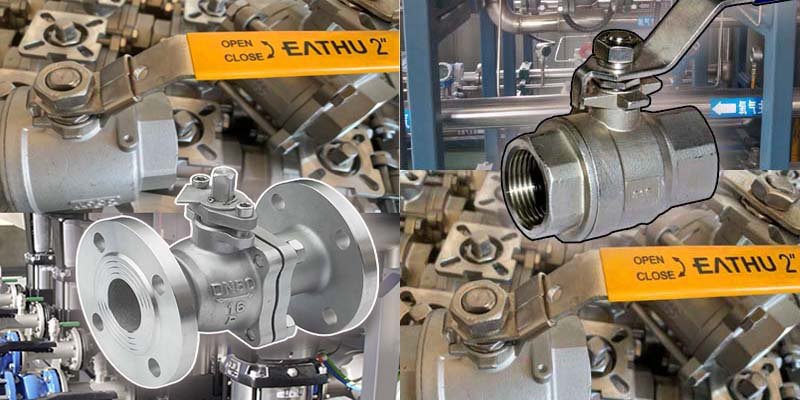

Ball valve is currently all the valves in the market, the most widely used a mechanical product, which is mainly composed of the valve body, seat, ball, stem and transmission device, through the actuator to drive the ball core rotation, to achieve the function of switching or regulation. In the chemical industry, environmental protection, water treatment, urban construction, machinery, including food and other industries, the application is wide, and very popular!

There are many kinds of ball valves, through the structure of the form, connection, pressure level, drive form, etc., can be combined into a variety of different functions of the product, but from the most basic point of view, the ball valve has a full bore ball valves and reduced ball valves of the two major categories of the difference between the points. Generally speaking, the valve ball inner diameter is less than or equal to 85% of the inner diameter of the ball valve port, known as the reduction of ball valves, while the ball valve inner diameter is greater than 95% of the inner diameter of the ball valve port, known as the full bore ball valves. So what is the difference between the two in the choice or application?

Definition

Full bore ball valve for equal width flow path, that is to say, from the flow in to the outflow of the aperture size is the same, its size can not be smaller than the standard value, roughly equivalent to the nominal diameter of the specifications, such as DN50 full bore ball valve flow path diameter also needs to be 50 or so.

Reduce the size of the ball valve runner entrance is wider than the runner diameter, the actual diameter of the runner is probably smaller than the specifications of a specification, such as DN50 reduce the size of the ball valve flow to the diameter of 38 or so, roughly the same as the specifications of DN40. In DN250 and shrink a specification, 250-600 shrink two specifications, 600 or more according to the actual situation.

Applicable Media

Full bore ball valves are generally used for conveying viscous, easy to slag media pipeline, because of its small fluid resistance, can be said that there is basically no flow resistance, can be convenient for regular scraping of wax blowing through the device, and can be used to reduce the size of the ball valve.

Reduce the diameter of the ball valve is suitable for conveying gases or physical properties similar to water on the pipeline, because of its weight than the full diameter of the ball valve is about 30% lighter than the flow resistance is only the same caliber globe valve of about 117. Favorable to reduce the pipeline load, reduce costs.

Applicable Processes

For the pipeline needs to be regularly cleaned, no matter what kind of media are transported, must be used full bore ball valves. Medium through the full bore ball valve will not reduce the flow, and flow resistance is small as the pipeline control of the ideal type of product, especially the strict requirements of the working conditions. Especially in the oil pipeline and gas pipeline in the main line black buried in the ground, must use full bore welded ball valve.

Reduce the diameter of the ball valve is suitable for some of the requirements are not high, the requirements of the flow resistance is small and other working conditions. When the inner diameter of the valve is greater than 80% of the inner diameter of the end of the pipe, the pipeline fluid through the ability to almost no effect. Many valves have a reduced diameter, generally controlled within 0.8, reduced on the one hand, reducing the valve's flow capacity, that is, the valve's Kv value, increasing the pressure drop at both ends of the valve, resulting in a loss of energy, for the pipeline, there is no great impact, perhaps increasing the scouring of the pipeline.

Advantages and Disadvantages

Installation space: Reduced diameter ball valve volume is small, so its installation space requirements are smaller. Its weight is about 30% lighter than the full diameter of the ball valve, which is conducive to reducing the pipeline load, reduce transportation load, reduce costs.

Cost: Reduced diameter ball valve than the full diameter ball valve price is lower than a grade, taking into account the cost-effective, the international generally default, adjacent to the pipe diameter using the same ball valve body. Such as dn32 and dn40, dn50 and dn63, dn90 and dn110, dn160 and dn200, dn250 and dn315 with the same ball.

Note: Due to the smaller inner diameter of the valve shrinkage ball valve, the valve stem is subjected to a small torque, it is more suitable to extend the service life of the valve switch. Especially the low torque design of large diameter valves. But the reduction can not shrink a lot, otherwise the system resistance will increase. But if you do not shrink the diameter, for one thing, is to increase the procurement costs, and then generally reduce the valve control characteristics, so that the adjustment effect becomes worse. For example, if the regulating valve is always used in a small opening, it will reduce the service life of the valve.

Conclusion:

EATHU ball valves have become the first choice in fluid control due to their outstanding performance and reliability. Its superior sealing performance is due to high quality sealing materials, which can effectively prevent leakage under high pressure and high temperature environments and enhance system safety. At the same time, the full bore design reduces flow resistance and ensures smooth fluid flow, adapting to a variety of working conditions and improving flow efficiency. In addition, after rigorous durability testing, EATHU ball valves show strong durability, with anti-corrosion and anti-wear characteristics, especially suitable for long-term use in harsh environments, significantly reducing maintenance costs. Whether in the petroleum, chemical, natural gas or water treatment industries, EATHU ball valves provide the ideal solution to meet the needs of a wide range of customers. Well-designed features make installation and maintenance easy, saving time and labor costs. EATHU also offers a customized service, designing ball valves of different sizes and materials to ensure optimal performance according to specific needs. Choosing EATHU ball valves will bring you an efficient, safe and reliable solution for your fluid control system.