The Ultimate Guide to Finding a Quality Valve Supplier

This article will provide an in-depth look at how to find and inspect quality valve suppliers to ensure that the partner you choose will meet your needs.

In fluid control systems, check valves play a key role in preventing backflow and ensuring proper pipeline operation. As a supplier of check valves, we understand the importance of choosing the right style of valve for your specific needs. This guide will introduce the various check valve styles, illustrate their differences, and explain their application scenarios in layman's terms. In the end, you will have a clear understanding of which check valve best meets your requirements.

A check valve, also known as a non-return valve, allows fluid (liquid or gas) to flow in one direction only. It will automatically prevent backflow, ensuring that the fluid does not flow back into the system, thus preventing damage or contamination.

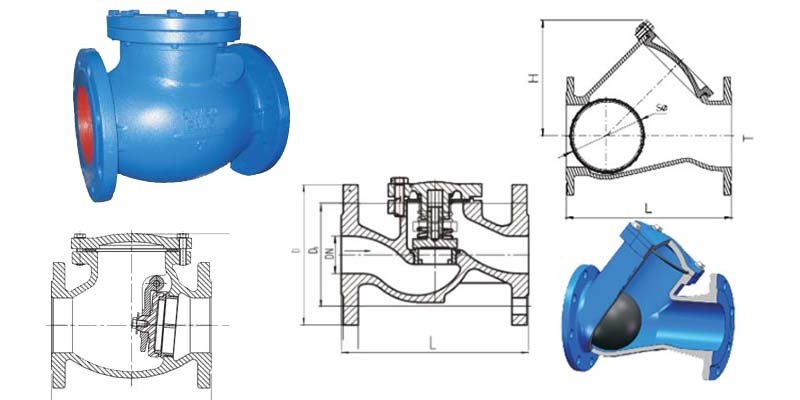

A swing check valve has a flapper that swings on a hinge or shaft, allowing the fluid to flow forward. When the fluid stops or flows backwards, the valve swings back to the closed position.

Applications: Swing-open check valves are commonly used in water and wastewater applications, HVAC systems, and irrigation systems. They are suitable for low velocity flows and are not suitable for pulsating flows.

Benefits: Simple design, low pressure drop, reliable operation on large pipelines.

Lift check valves have a flap that moves vertically in a guided chamber. Fluid lifts the flapper to allow flow, and gravity or reverse flow causes the flapper to fall back, sealing the valve.

Applications: These valves are typically used in steam, gas, and high pressure applications where a tight seal is required.

Advantages: Suitable for high pressure systems, good sealing performance, suitable for horizontal and vertical installation.

Ball check valvesutilize a sphere that moves in and out of the valve seat to allow or stop flow. As the fluid flows forward, the ball is pushed away from the seat, and as the fluid flows backward, the ball returns to the seat, sealing the valve.

Applications: Ball check valves are used in pump and compressor systems, water and wastewater treatment, and chemical processing.

Benefits: Compact design, can handle viscous fluids, and requires low maintenance.

Diaphragm check valves have a flexible diaphragm that opens and closes to allow or stop flow. The diaphragm bends to allow flow and returns to its original position to prevent backflow.

Application: Ideal for applications involving corrosive fluids, such as chemical processing and pharmaceutical industries.

Benefits: Suitable for handling corrosive and abrasive fluids with minimal leakage for sanitary applications.

Wafer check valves are thin and lightweight and are designed to be installed between two flanges in a piping system. They can have a variety of internal mechanisms, such as discs or plates, to prevent backflow.

Applications: For space-constrained systems, HVAC systems and water treatment plants.

Benefits: Compact design, easy installation, low pressure drop.

Silent check valves, also known as non-shock check valves, use a spring-assisted flap to control flow. The spring prevents the valve from slamming shut, ensuring smooth, quiet operation.

Application: These valves are used in systems that require noise reduction, such as residential plumbing and heating systems.

Benefits: Quiet operation prevents water hammer and responds quickly to flow changes.

Tilting disc check valves have a flap that can be tilted open and closed to allow or stop flow. The valve flap tilts in response to flow conditions and is balanced to minimize wear.

Applications: Commonly used in power plants, oil and gas industries, and water treatment facilities.

Benefits: Durable, low pressure drop, effective in both horizontal and vertical installations.

Mechanism of operation: each style has its own unique mechanism, such as swing, lift, tilt, etc., for controlling flow.

Pressure drop: Certain valves such as the baffle check valve have a lower pressure drop and are suitable for systems with higher pressure requirements.

Flow characteristics: different valves perform differently under high pressure and high speed flow, for example, lift check valves are suitable for high pressure while swing check valves are suitable for low speed.

Installation direction: Some check valves can be installed in any direction, while lift check valves have specific installation requirements.

Application suitability: Each valve style is suitable for a particular application depending on fluid type, pressure, temperature and system requirements.

Understand system requirements: Consider fluid type, pressure, temperature and flow characteristics.

Determine installation space: Check the space available for valve installation, compact designs such as the butt check valve fit in tight spaces.

Consider maintenance requirements: Choose a valve that matches your maintenance capabilities, such as a ball check valve for low maintenance costs.

Evaluate flow conditions: High pressure and high velocity flows are suitable for lift check valves, while swing check valves are more suitable for low velocity applications.

Noise reduction factors: For noise reduction, choose a quiet check valve to minimize water hammer and ensure quiet operation.

The selection of check valves must be based on the requirements of the actual working conditions, and different materials have different characteristics and scope of application. When choosing the material of check valve, it is necessary to consider according to the nature of the medium, temperature, pressure and other factors, in order to ensure the normal operation of the valve, and improve the service life of the valve.

For further information, please contact EATHU, EATHU is committed to providing high quality and cost-effective valves, we provide a variety of materials, certified standard valves, and valves through rigorous testing, in strict compliance with the ISO9001 quality inspection process and standards, we provide you with professional technical support and perfect after-sales service, ready to answer your questions and provide customized solutions!

Article Navigation

Casting Service

Casting Parts

Foundry

We are here to provide you with information about valves, technology, news, etc. We will keep you updated, as well as real-time updates on EATHU's company news. Feel free to contact us for proposals and quotations.

This article will provide an in-depth look at how to find and inspect quality valve suppliers to ensure that the partner you choose will meet your needs.

EATHU Valve has many years of experience in the valve industry, I use this article for you to explain the working principle of knife gate valve, if you have want to know more or want to discuss with us about the valve field stuff, welcome to contact me!

Valves according to the material can be divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316, etc.)。Here, Eathu answers your questions about the differences between cast iron and cast steel valves.