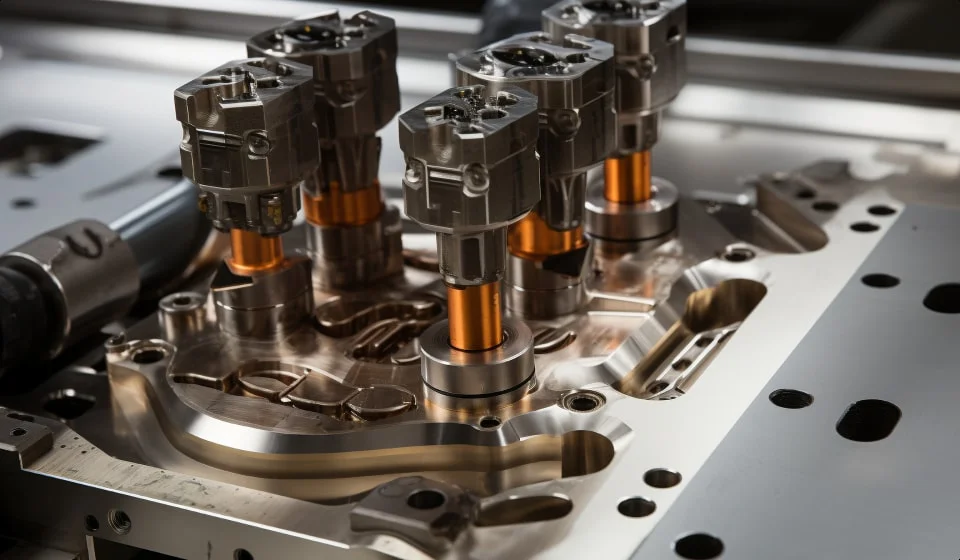

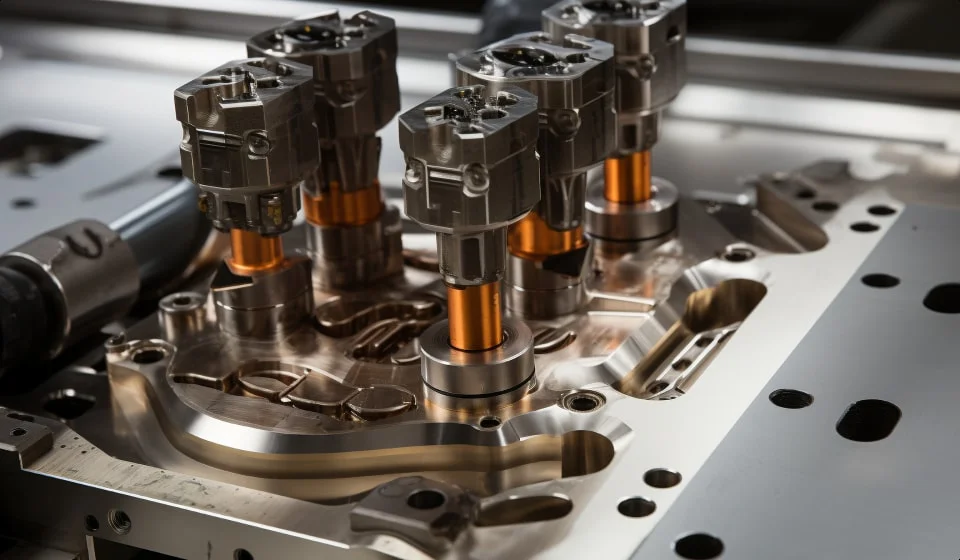

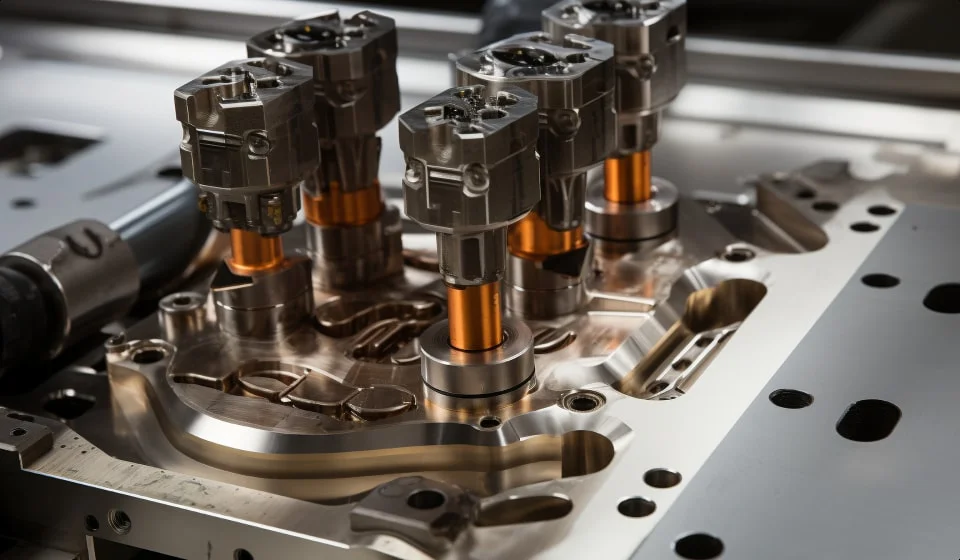

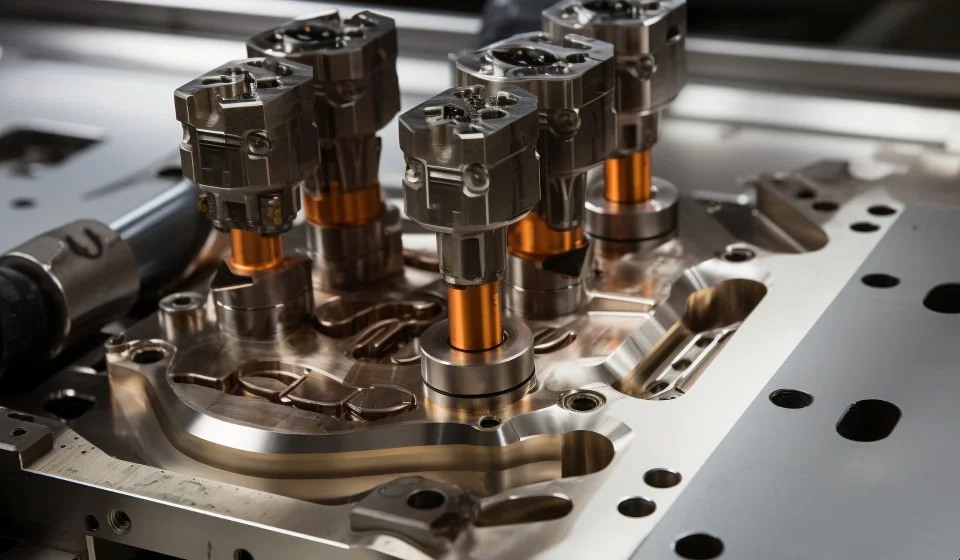

Excellent Metal Machining Service

EATHU provides perfect casting services, we according to customer needs, customized metal casting products, product drawing design, drawing optimization, process selection and advice, mold manufacturing, proofing, product manufacturing. Our engineers have 30 years of experience in the foundry industry and can provide the most appropriate advice to achieve the highest quality and precision.