Stainless steel ball valves, as an important fluid control element, are widely used in petroleum, natural gas, chemical, electric power, water treatment and other industries, and have become an indispensable part of modern industrial automation control systems due to their excellent performance and corrosion resistance. The main function of ball valves is to control the switching of fluids, flow regulation and the direction of fluids. Its market demand with the development of industry and gradually increase, especially in high temperature, high pressure and corrosive media control, ball valves show its irreplaceable advantages.EATHU for you to explain in detail will be the implementation of stainless steel ball valve standards

Stainless Steel Ball Valve Implementation Standards

Stainless steel ball valve implementation standards cover the design, manufacturing, testing, materials and other aspects to ensure that the ball valve in different working conditions can be stable and efficient operation. The global and national standards system provides manufacturers of stainless steel ball valves with uniform specifications to ensure their quality and safety. The main standards include:

International Standards (ISO standards)

ISO 17292 Stainless Steel Ball Valve

This is a standard for the design, manufacture and testing of industrial valves, in particular ball valves.ISO 17292 specifies the main requirements for ball valves, including their construction, materials, performance and applicable test methods. The implementation of this standard helps to ensure that ball valves can work efficiently and stably in various industrial environments.

ISO 5211 Stainless Steel Ball Valve

This standard is mainly applicable to non-electrical actuators for ball valves. It provides uniform design, dimensions and performance requirements for actuators of ball valves. Through the implementation of this standard, ball valves and actuators work more smoothly together, improving the reliability and efficiency of automated control systems.

ISO 14313 Stainless Steel Ball Valve

Pipeline valves for the oil and gas industry, including the design, manufacture, performance requirements and testing of ball valves. As the oil and gas industry requires high standard products, ISO 14313 provides a guarantee for the safety and durability of ball valves, especially for the transportation of high pressure, high temperature and corrosive media.

American Standard (ANSI/ASME Standard)

ANSI/ASME B16.34 Stainless steel Ball Valve

This standard specifies the design and dimensional requirements for valves with flanged, threaded or welded ends, including stainless steel ball valves. ANSI/ASME B16.34 is one of the globally recognized valve standards, ensuring that ball valves are able to withstand high pressures, high temperatures, and a variety of fluid mediums under operating conditions.

API 6D Stainless Steel Ball Valve

Specializing in valves for oil and gas pipeline systems, the API 6D standard covers the design, manufacture, testing and performance requirements for ball valves. The implementation of this standard ensures that ball valves can meet the high reliability and safety requirements in oil and gas transportation.

API 608 Stainless Steel Ball Valve

This standard applies to metal ball valves, especially those used in high-temperature and high-pressure environments, and specifies the design, material and performance requirements for ball valves.API 608 pays special attention to the durability and sealing of ball valves.

European Standards (EN Standards)

EN 1349 Stainless Steel Ball Valve

This is a standard for the design and testing of industrial ball valves, covering the requirements for stainless steel ball valves.EN 1349 regulates the structure, function and testing requirements for ball valves to ensure that they can work stably in a variety of industrial environments.

EN 12266-1 Stainless Steel Ball Valve

This standard specifies methods for pressure testing of valves, including airtightness and pressure resistance testing of stainless steel ball valves. Ball valves complying with this standard are able to operate under extreme conditions, providing good sealing and pressure resistance.

Chinese Standard (GB/T Standard)

GB/T 12237 Stainless Steel Ball Valve

Chinese standard GB/T 12237 covers the design, manufacturing and testing requirements for ball valves, especially in terms of valve size, connection methods and sealing performance. Most of the stainless steel ball valves on the Chinese market need to follow this standard.

GB/T 13927 Stainless Steel Ball Valve

This standard for pressure testing of valves also covers ball valves. It includes pressure test, air tightness test, etc. It ensures that ball valves can withstand pressure changes in the working environment to avoid leakage and failure.

GB/T 9113 Stainless Steel Ball Valve

This standard for flange connection valves, ball valves as a common flange connection valves, must comply with the requirements of the standard to ensure the stability of the connection and sealing.

Stainless steel ball valve market demand and development trend

Global Market Demand

With the acceleration of global industrialization, especially the rapid development of oil, gas, chemical, electric power and other industries, the demand for high-performance valves is increasing. Stainless steel ball valves with its corrosion resistance, high sealing, high temperature and high pressure resistance and other advantages, become an indispensable and important part of these industries. In the global market, the demand for stainless steel ball valves is growing, especially in the following areas of outstanding performance:

Oil and Gas Industry

oil and gas extraction, transportation and processing requires high-performance valve equipment, especially valves that can withstand extreme temperatures, pressures and corrosive media. Ball valves are widely used in this industry because of their good fluid control performance, easy operation and reliable sealing.

Chemical and Pharmaceutical Industries

The production process of chemicals and pharmaceuticals, often need to deal with highly corrosive or hazardous substances, which requires ball valves with strong corrosion resistance and high temperature resistance. In particular, stainless steel ball valves have become one of the mainstream valves in the chemical industry due to their superior chemical stability.

Water Treatment Industry

With the global water resources tension and water treatment technology progress, the demand for efficient and reliable water treatment equipment increases, stainless steel ball valves with its good sealing and corrosion resistance, widely used in the water treatment industry.

Energy Industry

In the process of energy transportation, power generation, valves play a vital role. Stainless steel ball valves are more and more widely used in electric power, nuclear power and new energy fields because of their good fluid control ability and high temperature and high pressure adaptability.

Future Market Trends

In the next few years, the market for stainless steel ball valves will show the following trends:

Intelligent and Automation

With the popularization of industrial automation, intelligent ball valves have become a new trend in the market. With sensors and automation control systems, ball valves are able to achieve more accurate flow control and troubleshooting.

Increased Demand for High-performance Ball Valves:

With the widespread use of high temperature, high pressure, corrosive environments, the performance requirements of ball valves will be more demanding, especially in the oil and gas, chemical and other industries, the demand for high-performance stainless steel ball valves will continue to increase.

Environmental Protection Requirements to Enhance:

The increasingly stringent global environmental regulations prompted stainless steel ball valve manufacturers in the design and production process to pay more attention to environmental requirements, such as the use of recyclable materials and environmentally friendly coatings, etc., to reduce the environmental impact of the valve in the operation process.

Conclusion

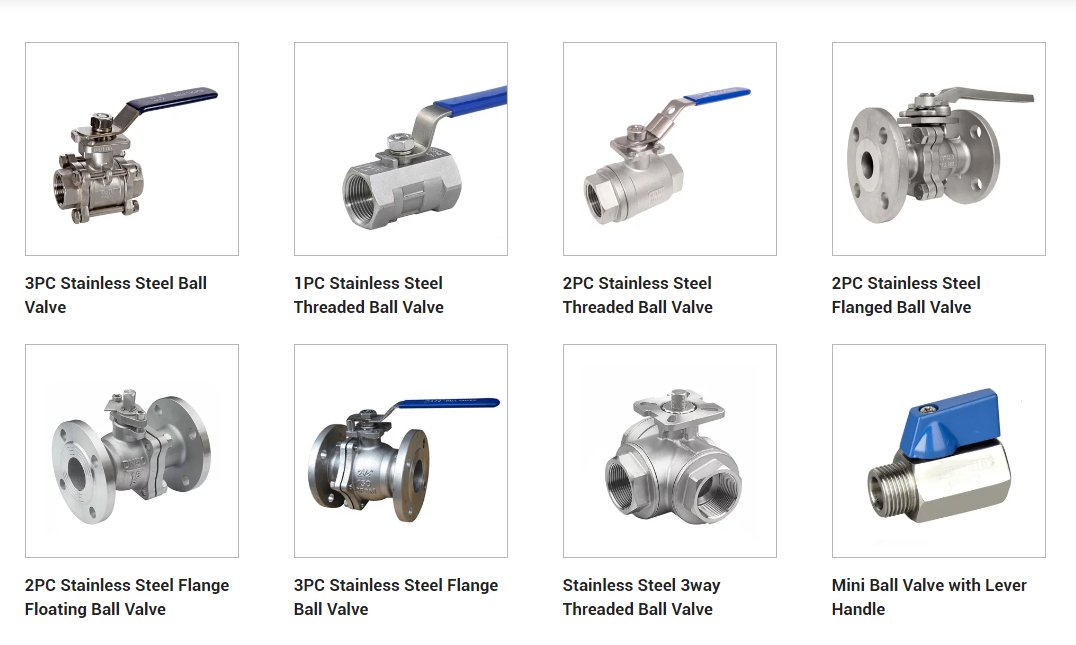

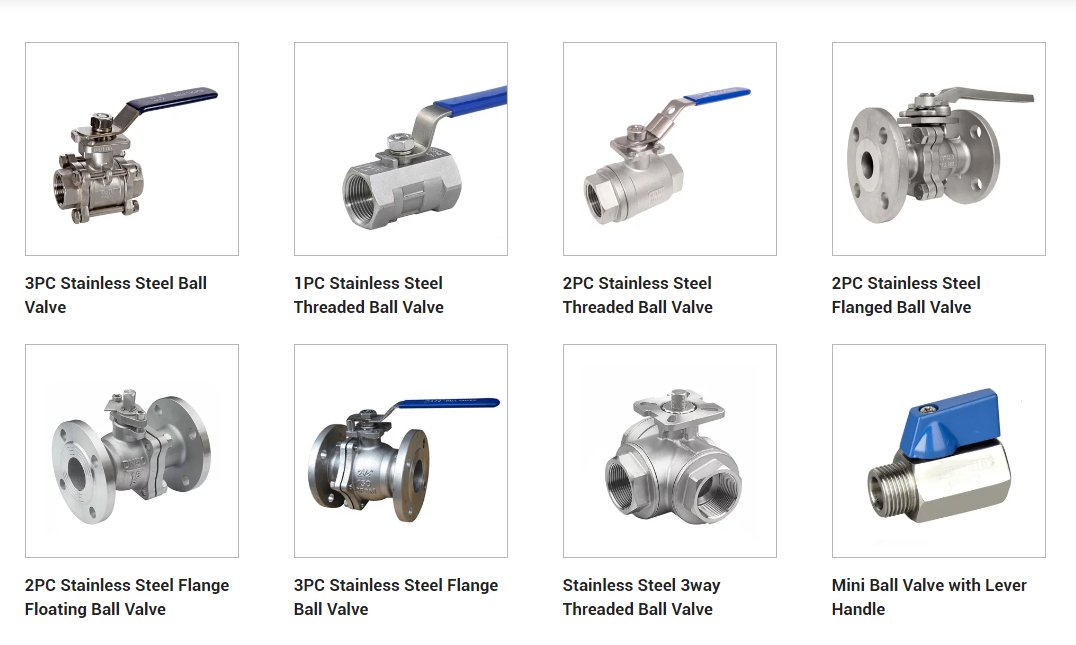

EATHU stainless steel ball valves, strictly following international standards, are made of high quality stainless steel material with excellent corrosion and high temperature resistance. With precise design and reliable sealing performance, our ball valves can ensure the safe and efficient operation of fluid systems. Whether in the chemical, oil, gas, power and other industries, EATHU stainless steel ball valves are able to cope with a variety of harsh working conditions, providing stable and long-lasting performance. Choosing EATHU ball valves, you not only choose the high quality, but also choose the peace of mind and security.