High Pressure Stainless Steel Ball Valve

Components

It consists of ball, valve body, stem, seal and handle. The production process of each component is different, the ball can be obtained by casting or forging after CNC machining, or can be directly obtained by CNC machining stainless steel rods, the valve body is obtained by precision casting, and the valve stem is mostly obtained directly by CNC machining or processed after forging, and the handle is obtained by casting.

Material

Ball, body and stem are made of 304, 316 or 316L stainless steel. Seals are PTFE, PFA or metal. And the handle is stainless steel or carbon steel.

Standard

The usual standards are ANSI, DIN, BS, GOST, and in the case of food and pharmaceutical applications, national standards for food and pharmaceutical valves.

Applications

Currently, high pressure stainless steel valves are used in the oil and gas, chemical, steam, pharmaceutical, and food industries where high pressure piping is required.

Choose A Better Manufacturer

When choosing a manufacturer of high pressure stainless steel ball valves, we need to consider not only the products they offer, but also their services to help us save more time to process more orders. A supply chain that operates efficiently will bring you more convenience.

Well-established and tightly managed supply chain

A perfect supply chain allows us to ensure the high quality and timely supply of raw materials and components, through close cooperation to obtain lower prices, strict quality control and procurement processes can ensure that high-pressure stainless steel ball valves have a higher quality from the source.

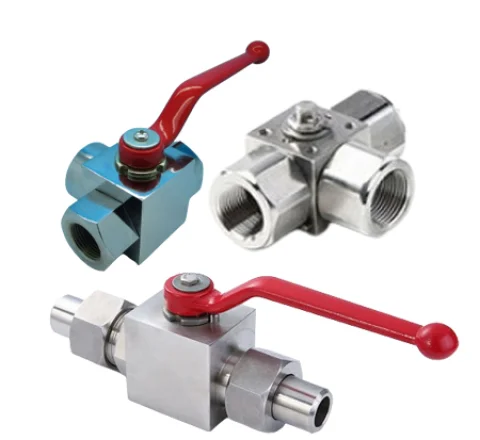

Rich variety of high pressure ball valves

An excellent manufacturer will provide a wide range of high pressure stainless steel ball valves, covering different specifications, connections and operation types to meet the needs of various industrial applications. From manual, pneumatic to electrically operated ball valves, a wide range of models and sizes are available and can be customized to meet specific customer needs.

Being able to offer stainless steel ball valves in different materials as well as different sizes, connections and operation types saves you the time of waiting and comparing multiple quotes and reduces a lot of silent costs. With a good manufacturer, you only need to post a purchase order to receive a more competitive offer.

Better Prices

A well-established supply chain allows us to save the cost of High Pressure Stainless Steel Ball Valve from multiple sources. Good manufacturers often have advanced equipment and experienced staff and can better schedule production according to the order, thus saving more material, time and energy costs.

More attentive service

Attentive service can save you more time and energy. From pre-sales consultation, technical support to after-sales service, a service that responds to your needs in a timely manner can effectively reduce the effort you spend on orders. You can complete one high quality order after another faster.