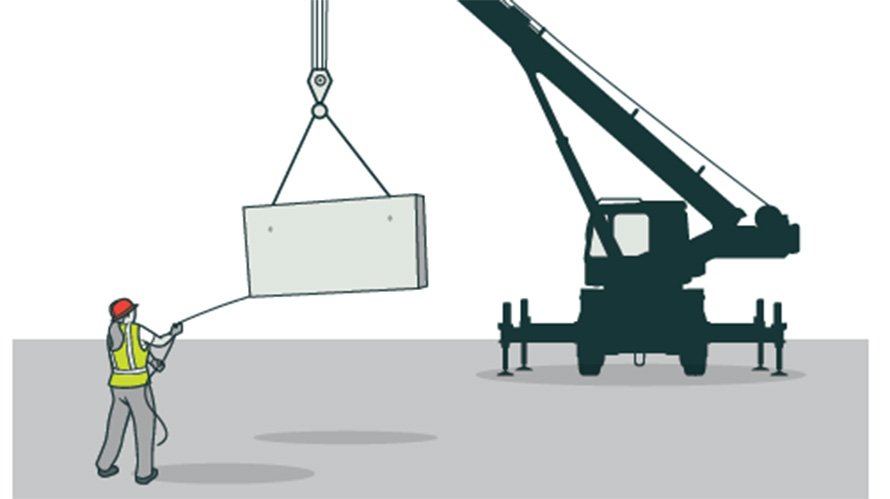

Precast concrete lifting clutches are essential components in the safe and efficient handling of precast concrete elements. These specialized lifting devices ensure that heavy concrete panels, beams, and slabs can be lifted, transported, and installed with precision. Understanding the types, design considerations, and proper usage of lifting clutches is crucial for ensuring safety and efficiency on construction sites. This guide provides a comprehensive overview of precast concrete lifting clutches, covering their types, working mechanisms, safety standards, and best practices for use.

What Are Precast Concrete Lifting Clutches?

Precast concrete lifting clutches are specialized lifting devices designed to engage with embedded anchors or lifting points cast into precast concrete elements. These clutches securely attach to the lifting anchors, allowing for controlled movement and positioning of concrete structures.

Importance of Lifting Clutches in Precast Construction

Lifting clutches play a vital role in modern precast construction by providing a reliable and safe means of handling heavy concrete components. Their importance includes:

Enhancing safety during lifting operations

Reducing the risk of structural damage

Improving efficiency in installation processes

Allowing for precise placement of precast elements

How Lifting Clutches Work

Lifting clutches function by securely engaging with lifting anchors or inserts embedded within the concrete. The locking mechanism ensures a firm grip, preventing accidental disengagement during lifting and lowering operations. The design of these clutches allows for quick attachment and release, minimizing downtime in construction processes.

Types of Precast Concrete Lifting Clutches

Standard lifting clutches are commonly used for general lifting applications in precast construction. They are designed for repeated use and provide a secure connection with compatible lifting anchors.

Swivel Head Lifting Clutches

Swivel head lifting clutches offer enhanced flexibility by allowing movement in multiple directions. This type of clutch is beneficial for lifting precast elements at various angles, making it ideal for complex installation scenarios.

Ring Clutches

Ring clutches consist of a durable ring mechanism that engages with the lifting anchor. These clutches are commonly used in heavy-duty lifting applications, offering high load capacity and secure attachment.

Quick-Release Lifting Clutches

Quick-release lifting clutches are designed for rapid attachment and detachment, making them ideal for high-efficiency lifting operations. Their design allows for easy handling, reducing labor effort and improving workflow on construction sites.

Safety Considerations for Lifting Clutches

Each lifting clutch is designed to handle a specific load capacity. Exceeding the weight limit can result in structural failure and pose serious safety hazards. Always ensure that the lifting clutch used matches the weight and load distribution of the precast element.

Inspection and Maintenance

Regular inspection and maintenance of lifting clutches are essential to ensure their continued reliability and safety. Key inspection points include:

Checking for wear and tear on the clutch mechanism

Ensuring that the locking mechanism is functioning properly

Inspecting for any signs of corrosion or material degradation

Proper Usage Techniques

Improper use of lifting clutches can lead to accidents and damage to the concrete elements. Best practices for safe usage include:

Using the correct lifting angle to prevent uneven weight distribution

Ensuring that the clutch is fully engaged with the lifting anchor before lifting

Avoiding sudden movements that may cause excessive stress on the lifting system

Best Practices for Using Lifting Clutches

Choosing the appropriate lifting clutch depends on various factors, including the weight, shape, and lifting conditions of the precast element. Consulting with manufacturers and referring to technical specifications can help in selecting the right clutch for the job.

Training and Certification

Proper training is crucial for operators handling lifting clutches. Certification programs ensure that workers are knowledgeable about safety procedures, correct attachment techniques, and emergency protocols related to lifting operations.

Compliance with Industry Standards

Lifting clutch systems must comply with industry standards and regulations to ensure safety and performance. Adhering to national and international safety standards helps prevent workplace accidents and ensures reliability in lifting operations.

Conclusion

Precast concrete lifting clutches are indispensable tools in the construction industry, providing safety, efficiency, and precision in handling heavy precast elements. Understanding the different types of lifting clutches, their safety considerations, and best practices for usage ensures optimal performance on construction sites. By selecting the right lifting clutch, conducting regular inspections, and adhering to industry standards, construction professionals can maximize the effectiveness of precast concrete lifting operations while maintaining high safety levels.