A wheel hub is a key component in a vehicle's wheel assembly, acting as the connection point between the wheel and the axle. It allows the wheel to rotate smoothly around the axle, which is essential for the vehicle's movement. The hub typically houses bearings, which reduce friction and enable the wheel to spin with minimal resistance.

WHEEL HUB MOlD DEVELOPMENT

A metal casting project typically starts with mold development, where key factors are carefully considered. Our skilled technical team will analyze your drawings to choose the most suitable casting method and devise an optimal solution that ensures high quality, reduces costs, and enhances production efficiency.

WHEEL HUB CASTING

At EATHU, we take pride in our comprehensive production process that spans every stage of wheel hub manufacturing. With our high production capacity and state-of-the-art wax pattern making machines, shell making lines, and casting systems, we are equipped to handle projects of nearly any scale. Additionally, we have made significant strides in optimizing our supply chain, resulting in substantial cost reductions throughout the production process.

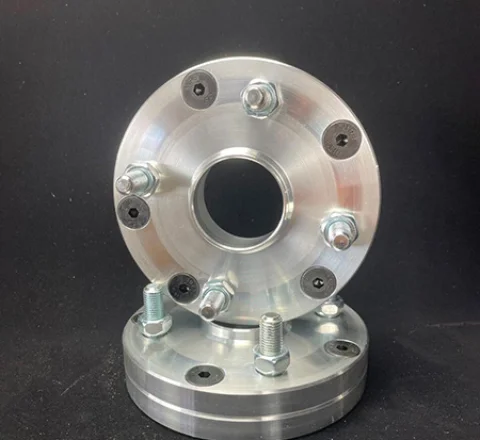

WHEEL HUB MACHINING & SURFACE TREATMENTS

For years EATHU has been dedicated to the improvement of the machining process. Now our top-notch machining techniques ensure pin-point accuracy and a smooth surface.

After the machining is finished, the final step is about the surface treatment and quality control. Each type of wheel hubs might require special coating for their anti-corrosion performance. We’ve established a quality control system where every step of manufacturing is closely monitored and inspected.

QUALITY INSPECTION PROCESS

We carry out four-stage inspections: Pre-Production Inspection, During Production Inspection, Pre-Shipment Inspection, and Container Loading/Unloading Inspections.

Before the production begins, pre-production inspection is in place to make sure that the quantity and quality of the raw materials meet the standards; during the production, each batch of products will be closely examined and tested so that any deviations can be identified. Before the products can be shipped to our clients, pre-shipment inspection, and container loading/unloading inspections are also carried out.