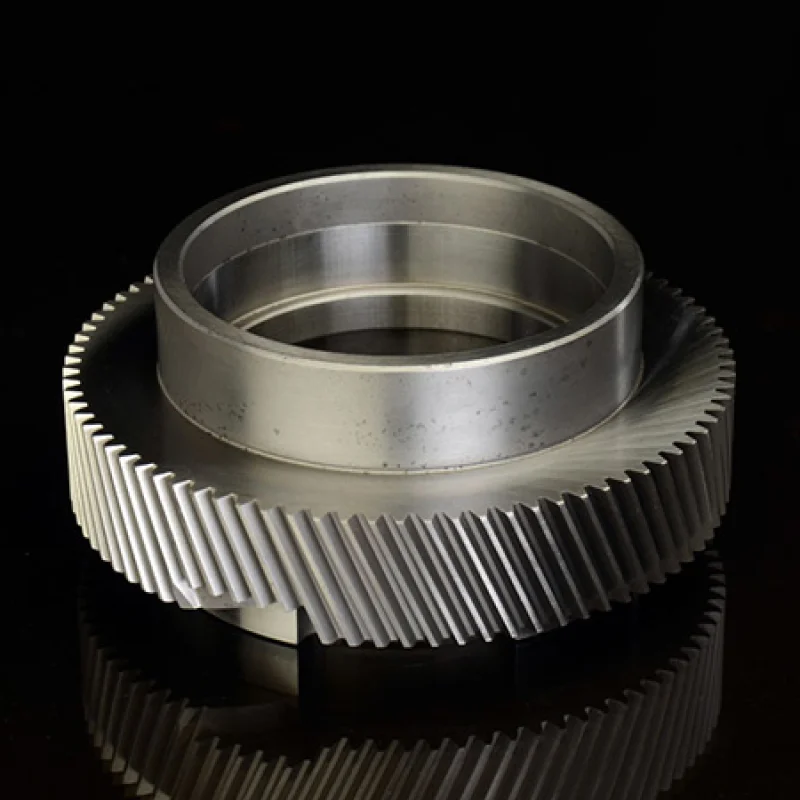

Ring gears are ring shaped gears. Auto parts casting is the process where molten metal is poured into the mold to create auto components. EATHU has played a role in the auto parts casting industry. For years, we’ve been working with some of the known players in the field, have undertaken projects from all over the world.

RING GEAR MOlD DEVELOPMENT

A metal casting project usually begins with a mold development during which important factors will be taken into consideration. Our experienced technical team will select the appropriate casting method based on your drawings and work out a better solution to ensure quality while reducing costs and improving production efficiency.

RING GEAR CASTING

At EATHU, we are proud of being a manufacturer to have a production process that covers every step of ring gear manufacturing. We have a great production capacity. Thanks to our advanced wax pattern making machines, shell making lines and casting lines, we are confident that we can handle projects of virtually any sizes. We’ve also put great efforts into the optimization of supply chains, which largely reduces costs during production.

RING GEAR MACHINING & SURFACE TREATMENTS

For years EATHU has been dedicated to the improvement of the machining process. Now our top-notch machining techniques ensure pin-point accuracy and a smooth surface.

After the machining is finished, the final step is about the surface treatment and quality control. Each type of ring gear might require special coating for their anti-corrosion performance. We’ve established a quality control system where every step of manufacturing is closely monitored and inspected.

QUALITY INSPECTION PROCESS

We carry out four-stage inspections: Pre-Production Inspection, During Production Inspection, Pre-Shipment Inspection, and Container Loading/Unloading Inspections.

Before the production begins, pre-production inspection is in place to make sure that the quantity and quality of the raw materials meet the standards; during the production, each batch of products will be closely examined and tested so that any deviations can be identified. Before the products can be shipped to our clients, pre-shipment inspection, and container loading/unloading inspections are also carried out.