Grooved Butterfly Valve Features

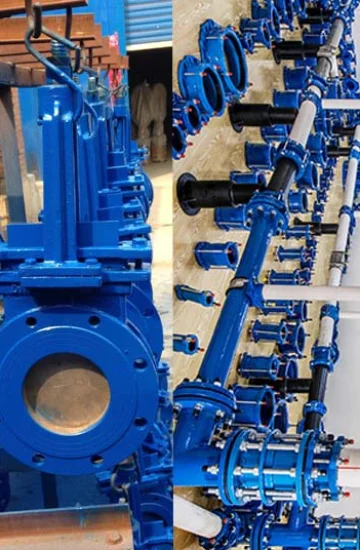

Generally divided into handle type groove butterfly valve, worm wheel type groove butterfly valve, worm wheel type groove signal butterfly valve. Models from DN50-DN300 each model has a specific height structure length and so on, you can contact us to see the specification table.

They are stable and reliable in usability, very easy to operate, rotate 90 degrees.

Small and lightweight, can be installed in any position pipeline.

When installing the valve, the direction of pipeline media flow can be disregarded, supporting bidirectional flow.

Groove butterfly valve due to the principle of three eccentric structure, the sealing surface of the valve plate and the valve seat sealing between the valve plate and the valve seat is to rely on the torque of the transmission device so that the valve plate is pressed to the valve seat. Positive flow state, the higher the medium pressure sealing squeeze the tighter. When the flow channel media countercurrent with the media pressure increases between the valve plate and the valve seat unit pressure is less than the media pressure, the seal began to leak.

Grooved Butterfly Valve Application

Groove butterfly valve is mostly used in water supply and drainage, fire fighting, petroleum, chemical, pharmaceutical, iron and steel pipelines as a cut-off or regulation.

It can also be used for the control of solid materials, often in the bottom of the tank as a discharge valve to use, such as cement tanks, stone powder tanks, etc., the bottom of the tank, used to discharge and rapid cut-off.

Why Buy Grooved Butterfly Valves from EATHU?

Capability:

Eathu is the top casting factory in China with rich experience and is the valve supplier for many companies in the world. Our monthly production capacity reaches tens of thousands of tons. Our "Eathu" has been recognized in the market, which represents our customers' trust in us and is our advantage.

Quality control:

1. We will make strict debugging for each part of the trench butterfly valve, whether it is manual, pneumatic, hydraulic or electric, before leaving the factory.

2. We control the quality of the valve from the process, material source, production process, valve assembly, skills and technology in all aspects, to achieve 100% testing. And we have obtained ISO9001 certificate, which is the market's recognition of our quality.

3.Eathu's valves are manufactured in accordance with international standards, such as DIN/ANSI/ BS/EN/GOST, and we provide relevant certificates.